Coconut Processing Production Line

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

The coconut processing equipment production line typically refers to a series of mechanical devices and processes used to manufacture coconut and its derivative products. Here is an overview of the main components of these production lines:

1.Coconut Harvesting and Transportation - After harvesting, coconuts need to be transported to the processing plant.

2.Cleaning Equipment - Coconuts are thoroughly washed to remove dirt and impurities before processing.

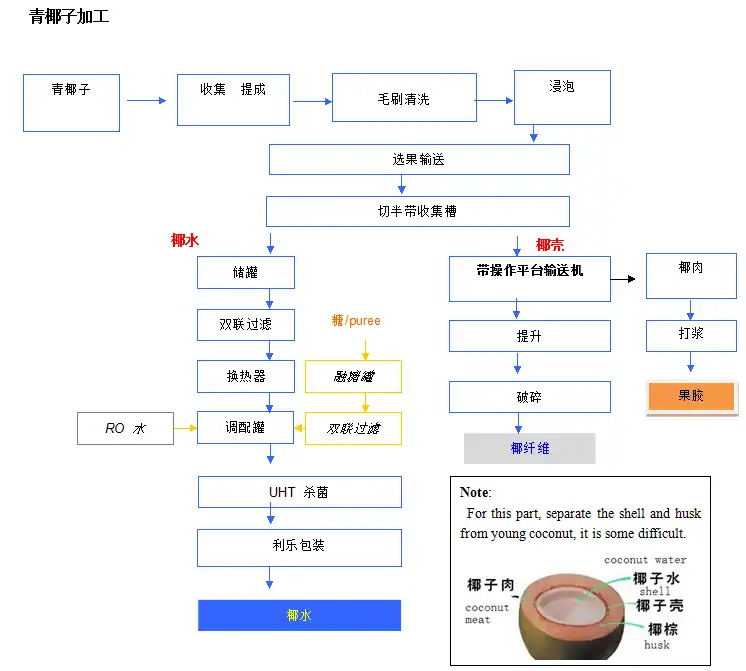

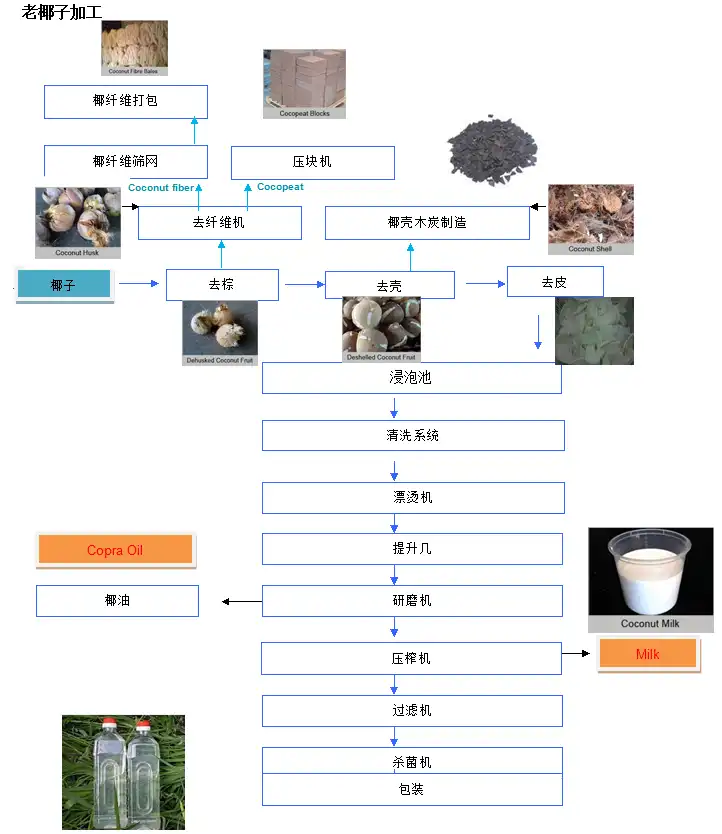

3.Husk Removal and Separation Equipment - Machinery that removes the hard shell of the coconut and separates the coconut meat from the coconut water.

4.Coconut Meat Processing Equipment - Turns coconut meat into products like coconut shreds, slices, or powder.

5.Coconut Water Treatment Equipment - The coconut water undergoes processes such as filtration and pasteurization for direct sale as a beverage or further processing.

6.Oil Extraction Equipment - Extracts coconut oil from the coconut meat, involving pressing and refining processes.

7.Packaging Equipment - Properly packages the processed coconut products for storage and transportation.

8.Quality Control - The production line may include multiple quality checkpoints to ensure products meet standards.

9.Automation Control Systems - Modern production lines are usually equipped with automated control systems to improve efficiency and consistency.

10.Waste Management - Waste generated during the production process is treated with specific equipment to minimize environmental impact.

The design and configuration of the coconut processing equipment production line will vary depending on specific needs and production scale. Some production lines may be highly automated, while others may focus more on manual operations. It is crucial to ensure that all parts of the production line work effectively together to produce high-quality coconut products.

Send Inquiry